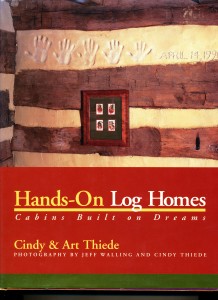

Country Living magazine article… part 3

Here are the second and third pages of the Country Living article on this cabin… which create sort-of a centerfold… yeah, I know… ooh la la. 😉

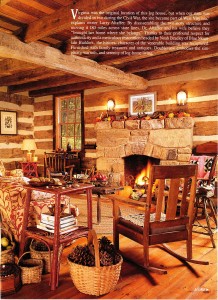

I’d like to point out the “summer beam” in the ceiling. This large oak timber runs the length of the first floor, right down the center of the rooms and provides added strength to the joists above.

This summer beam was not original to the cabin and was added by us after the joists were in place and it became obvious that there was too much “bounce” on the second floor.

I’m not certain if the bounce was something the original owners put up with, or if they had some kind of interior framed walls downstairs that helped support it. But, we felt that the situation was unacceptable and that something needed to be done.

It was quite a challenge to install this extremely heavy beam up into place. But, our efforts were rewarded with a greatly strengthened floor system.

I also think that this hewn timber adds tremendously to the look of the room.

So, what do you think? Would you like to kick back on the couch and enjoy the fire for a bit?

Originally posted 2015-05-12 18:23:33.