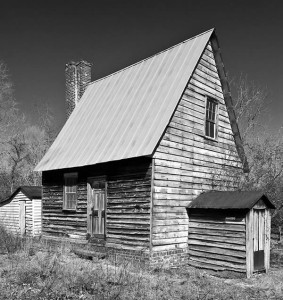

Quaker stone home

A Quaker stone home… notice the quality of the stone and it’s workmanship. Most impressive.

I can’t help but wonder what the folks of “years gone by” would think of our use of old wagon wheels as decorative items. So many old homes and cabins have them leaning against the home for an aging affect. I wonder if our descendants, a hundred years from now, will use 21st century spare tires to add a bit of our vintage era to their homes?

Originally posted 2015-10-15 19:29:09.