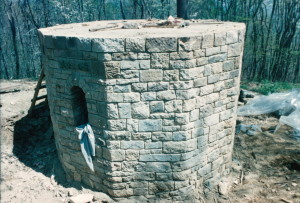

An “Undecagon”

Noah Bradley2019-06-29T10:29:50+00:00It’s an “Undecagon”… an eleven sided object. Built of solid stone, near the top of a mountain, and under construction in this photo. Notice the arched doorway, and there are two arched windows. I think the most impressive detail are all the cornerstones, each cut by hand and chisel to create a 127 degree angle corner (inside and out).

Originally posted 2015-01-29 15:40:38.