Chinking… from then, to now

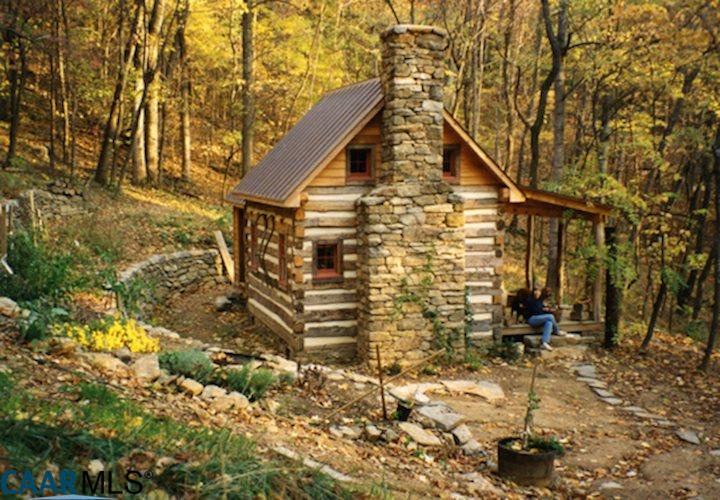

Noah Bradley2019-06-29T10:28:12+00:00Here is an example of primitive chinking.

In the early days of this country chinking, or “daubing”, would have had to be frequently repaired or replaced.

When lime became available chinking would become more durable and pleasing to the eye.

Later, cement would prove to be the best material… low cost, attractive, effective, and long lasting.

And then, man invented an expensive, synthetic, toxic, petroleum-derived product that was designed to look like cement as much as possible. This manufactured goo is messy to install and clean up after, and it’s durability is unproven (plastic products don’t have the best record of holding up under direct sunlight) But people buy it… why? 1) there are salesmen and businesses that promote it (for profit) 2) there are brochures touting the benefits of it (whose going to produce a brochure or sales team for cement chinking?) and 3) it’s human nature to assume that the latest product… the most expensive choice… is the best choice.

Originally posted 2016-03-20 15:23:18.