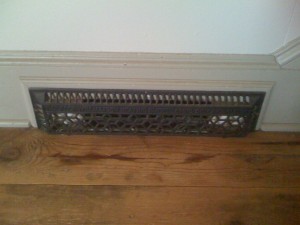

Floor vents

Noah Bradley2019-06-29T10:51:35+00:00The lowly floor vent.

So, often overlooked in even the finest homes and restorations.

At the end of a construction project most homeowners just want to be done with the construction process, no more decision making, and “looking for other options”, thank you very much.

The budget has been blown and the house is weeks, or months, behind schedule. The heating/air conditioning subcontractor only knows of the standard grills that he puts in every home and looks confused when you comment that his cheap louvers look terrible slapped onto vintage flooring.

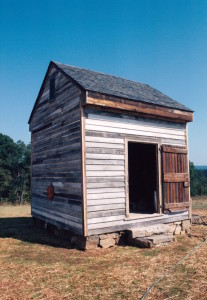

The urge is nearly overwhelming to just “get her done”. But I have found that when I return to homes that I have built that it is finishing touches like this that my eye is attracted to, and that my soul gets the greatest satisfaction from, that I finished the race well.

So, I make sure and give this finishing touch thought well ahead of time.

There are manufacturers of finer grills out there… but they still look a bit too “manufactured” for my taste. Although, I have gone this route when all else failed.

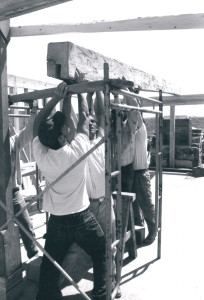

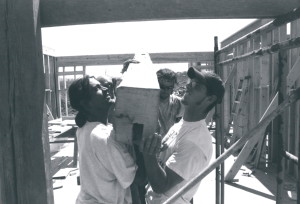

I like to either custom make them myself out of scrap lumber from the flooring. Or seek out alternatives at salvage yards. These metal grates all came from an old decorative oil stove that I bought and disassembled.

I was pleased… but maybe I just obsess about details too much. What do you think?

Originally posted 2015-02-28 16:24:11.