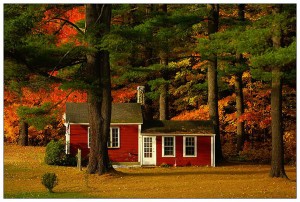

A country cottage

Noah Bradley2019-06-29T11:02:57+00:00Is this little red house trying to hide behind that pine tree? lol

What a sweet little home.

This house has been “placed” perfectly… visually she is safely tucked-in next to the hillside behind her.

I would have designed and built the addition a little differently… perhaps recessing it a bit so that the charm of the main part of the house was more up “front and center” and thus focusing my eye mainly on it.

But other than that, I’m green with envy over this red charmer.

Originally posted 2015-10-06 14:34:58.

What will your legacy be?

Noah Bradley2019-06-29T11:02:26+00:00Stone walls.

Stone roof.

Zero maintenance.

And a joy to look at!

What a charmer.

The life expectancy of such a structure (if it can avoid earthquakes and bulldozers)?… certainly hundreds of years… perhaps thousands of years.

What else can a person do during a lifetime that can impact and bless people that far into the future?

Originally posted 2015-09-24 16:18:32.